Latest

SA Hip Hop

Tiga Maine – Trenches ft. Mseventy DeeTee & Sauwcy mp3 Download free Finally the wait is over as high talented rapper and hit maker Tiga Maine who have been …

Amapiano Music

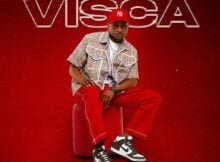

Visca – Ngiyaz fela ft. Daliwonga & Murumba Pitch mp3 Download free Finally the wait is over as high talented record producer and performer Visca who have been making …

Amapiano Music

Visca – Into encane ft. Mas Musiq, Aymos & Madumane mp3 Download free Finally the wait is over as high talented record producer and performer Visca who have been …

Amapiano Music

Visca – Celeb ft. Felo Le Tee, Genaro, Zulu Tariana & M.J mp3 Download free Finally the wait is over as high talented record producer and performer Visca who …

Amapiano Music

Visca – Cheese Melrose ft. Semi Tee, Ma Lemon & Kammu Dee mp3 Download free Finally the wait is over as high talented record producer and performer Visca who …

Amapiano Music

Visca – Ae Suke ft. Kabza De Small & Young Stunna mp3 Download free Finally the wait is over as high talented record producer and performer Visca who have …

Album

Visca – Through Thick And Thin EP zip mp3 Download free 2022 Album Finally the wait is over as high talented record producer and disc jockey Visca who have …

Amapiano Music

Visca – Visca Vimba ft. Dj Maphorisa, Murumba Pitch & Daliwonga mp3 Download free Finally the wait is over as high talented record producer and performer Visca who have …

Amapiano Music

Visca – Stop It ft. Kabza De Small mp3 Download free Finally the wait is over as high talented record producer and performer Visca who have been making lots …

Amapiano Music

Mr Pilato, Ego Slimflow & DJ Maphorisa – Ke Rata Byala ft. SJE Konka & T.M.A_Rsa mp3 Download free New Money Gang Records top notch music artists and hit …

Amapiano Music

Visca – UDlala Ngami ft. DJ Maphorisa & Nkosazana Daughter mp3 Download free Finally the wait is over as high talented record producer and performer Visca who have been …